Description

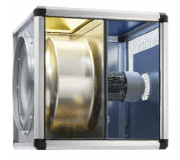

GigaBox are real multi-functional options that offer almost unlimited flexibility in various applications.

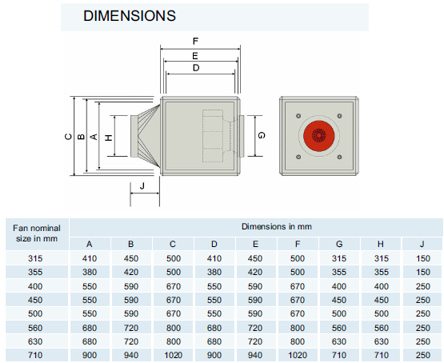

Compact frame construction and assembly-friendly accessories make a variable and thus optimal adaptation possible by simply repositioning the casing panels to the structural conditions. With five or (with series T120) three possible discharge directions this gives design flexiblity to suit all site conditions. All types have integrated crane hooks for easier positioning as standard.

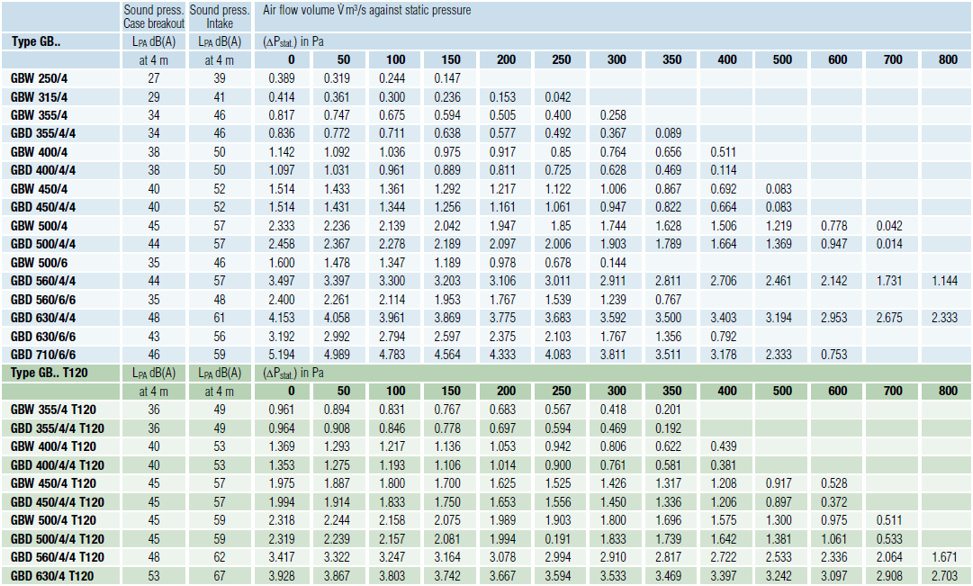

They are particularly suitable for medium to higher air flow volumes against high resistances in ventilation systems of every type. Furthermore, the new series GB..T120 is suited for extraction of dirty, hot air up to 120°C. Altogether, 26 models are available with air flow volumes from 1400 to 19000m³/h for duct diameters 250 to 710mm.

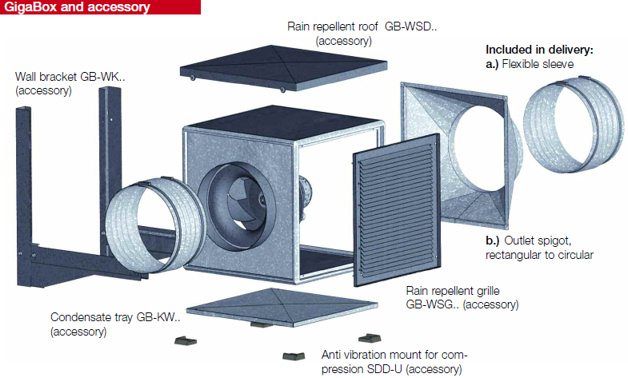

GigaBoxes from Helios are delivered complete with: 1) Discharge adapter from square to circular ducted system for low-loss discharge. 2) Flexible sleeves to reduce vibration transmission and for the connection to ducts in the usual standard diameters.

Backward curved high output centrifugal impeller guarantees an energy-efficient operation at low noise emission.

The double-walled, removable 20mm thick side panels are noise and temperature insulated with flame-retardant mineral wool. This allows for a variable installation and simple inspection access. Extensive accessories like wall bracket, condensate spigot (for GB..T120 included in delivery), external weather louvres to cover the exhaust opening, outdoor cover hood for protected outdoor installation ensure for the necessary flexibility on site.

GigaBox for air flow temperature up to max. 120° C

GB T120: The motor which is located outside of the air flow is separated from the impeller through a temperature insulated partition panel. The motor-impeller-unit is removable without disassembly of the ducting.

Assembly of the discharge adapter of GB T120 with centrifugal discharge direction to the top or to the side.

GB T120 with simply removable inspection cover.

The T120 model impresses with outstanding benefits: 1) Airflow temperature up to max. 120°C. 2) Motor located outside of air flow 3) Temperature insulated partition panel between motor and impeller, lined with 20mm thick flame-retardant mineral wool. 4) Easily accessible motor-impeller-unit, removable without disassembling the system components. 5) Inspection cover with handle, simply remove for cleaning and maintenance. 6) Condensate collector with condensate spigot included in delivery. 7) Accessory components suitable for use to max. 120°C.